|

1. Placing

an order: Custom

orders are usually taken over the phone. However, we can accept e-mail

orders as well as faxes. During the phone conversation, we are able to

recommend a camshaft profile to suit your specific needs. We have over

3000 different profiles to choose from; profiles for hydraulic, solid,

flat tappet, as well as roller camshafts. We are able to grind

everything from a 2 hp. Briggs & Stratton to a Top Fuel Dragster.

2.

Pre grinding process: The

first step is to inspect the camshaft to see if it needs any welding or

other repairs. After the repairs are made, it is cleaned in a

ceramic media solvent bath. This gentle scrubbing action removes

rust, grease, and baked on oil. The next step in the camshaft grinding

process is where the camshaft is verified for straightness and the centers

are verified for true. The centers are used to drive the camshaft,

along with the dowel pin or keyway. The main bearing area is

straightened within one thousandths of an inch. This verifies that the

profile will be in exactly the same location as when in the head or in the

block.

3. Grinding

your custom or "Exact-cut Restoration-Vintage" Camshaft: The

first step is to set up the cam grinding machine for the application that

will be performed.

This is accomplished by loading the desired profile onto the tracking

headstock. Different camshafts have different firing orders. The

firing order is set by the "index" plate. Placed on next

is the actual grind profile that will be used during regrinding. These

"masters" are exact replications of camshafts that we've ground

previously. This allows us to duplicate the exact profile on the

core that has been selected. The profiles are tracked onto the cams, and

any custom lobe separations can now be made manually using the headstock.

When we bring a lobe center "in" or "tighter," the

"power band" is shortened. Racers use this method to keep

their race cars "in the power". Most of the computer

controlled cars require the wider lobe separation.

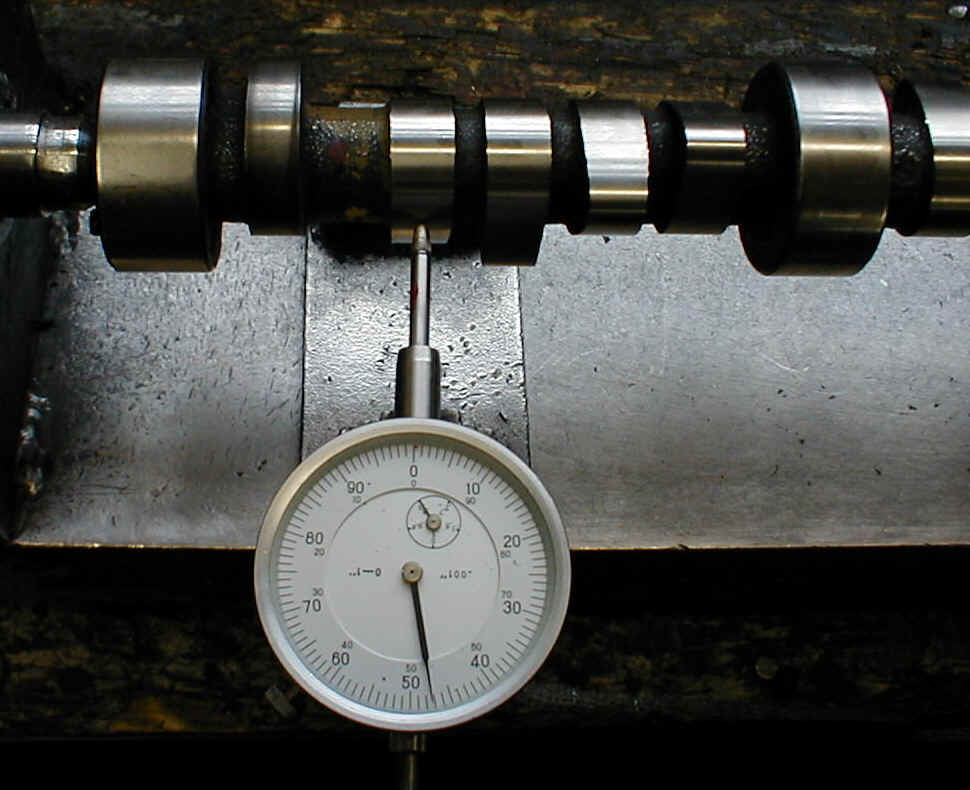

4. Post

grinding quality control: This

process is performed on every camshaft that we produce. The camshafts are checked for straightness to verify that they didn't bend

during the grinding process. After they are straightened to less than 1/2

thousandths on the main bearing areas, each lobe is checked to ensure they

are within tolerances for "run-out". If it not within tolerance,

it is rejected and returned back to the grinder to be reworked.

After every lobe is checked and has

passed inspection, the mains are taped with protective wrap in preparation

for the Parco surface treatment.

The camshafts are checked for straightness to verify that they didn't bend

during the grinding process. After they are straightened to less than 1/2

thousandths on the main bearing areas, each lobe is checked to ensure they

are within tolerances for "run-out". If it not within tolerance,

it is rejected and returned back to the grinder to be reworked.

After every lobe is checked and has

passed inspection, the mains are taped with protective wrap in preparation

for the Parco surface treatment.

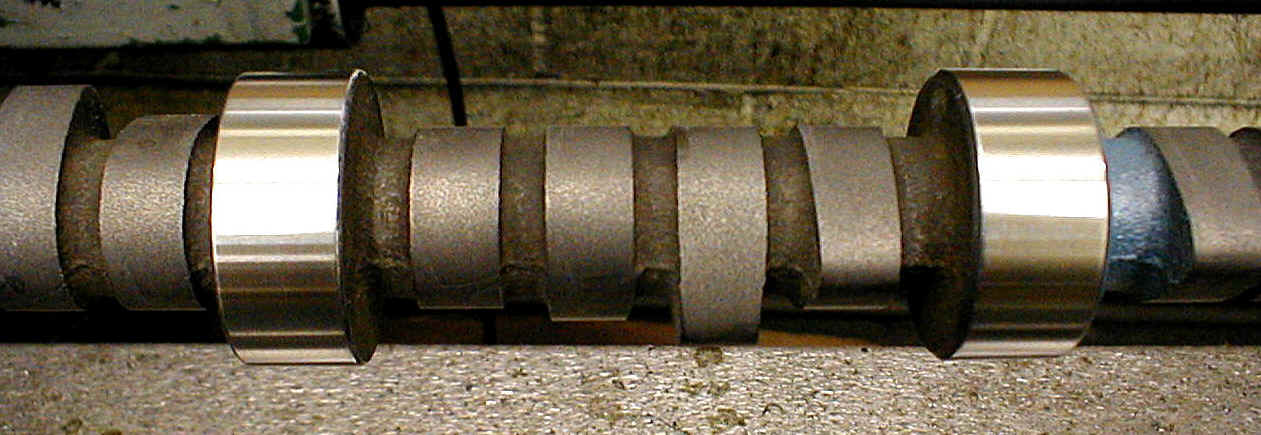

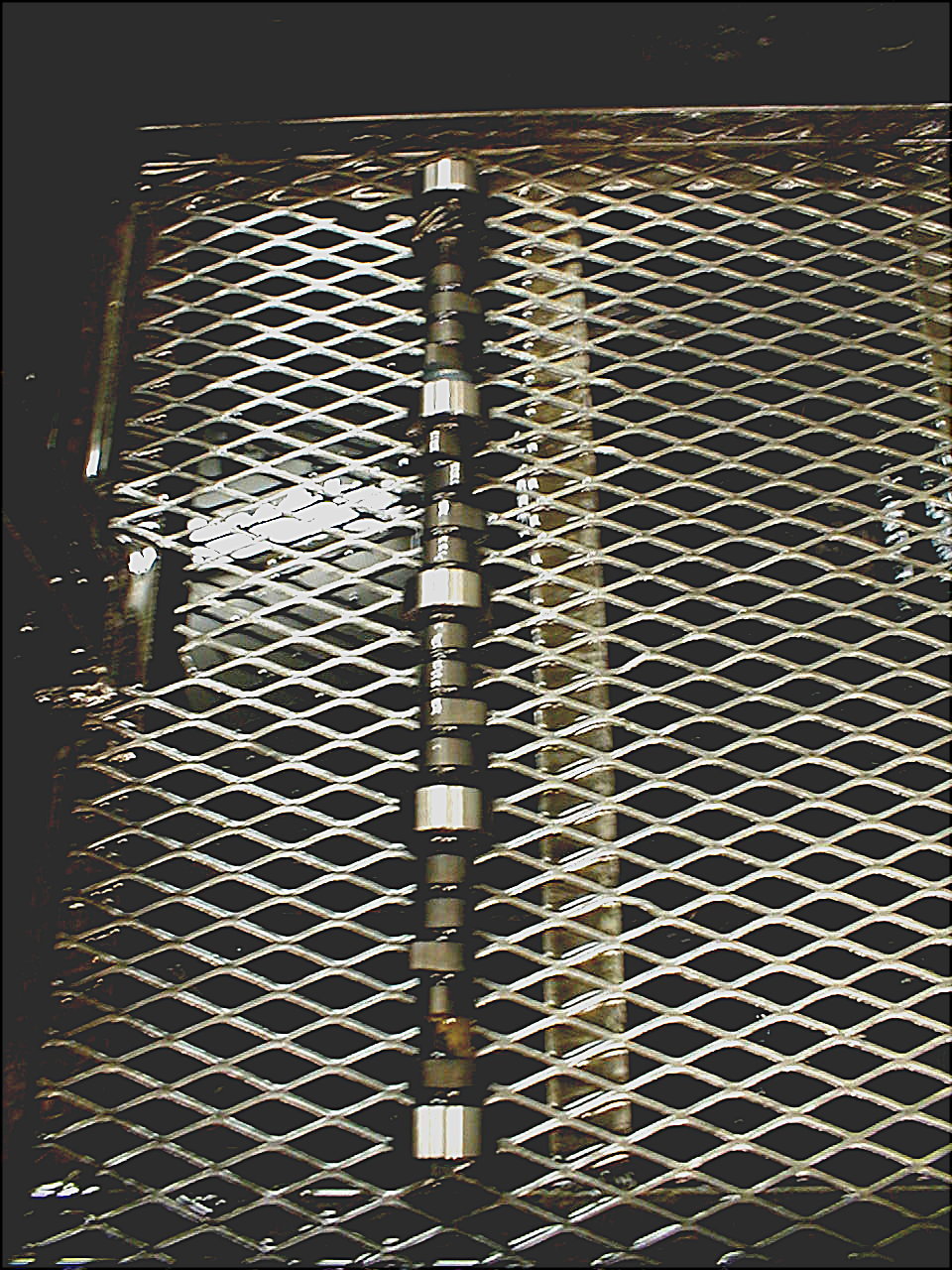

5.

Surface treatment process:

This is a surface treatment that is done to

all of our cast iron camshafts. It is a phosphate coating that inhibits

rusting on the lobe areas. This is done in a heated solution of Parco

Lubrite-2. The camshafts are hung evenly on a rack. They are then

submerged into the 200' F solution for approximately 30 minutes which will

allow appropriate coating. Under a microscope, the surface appears to have

"fish scales." This helps retain pre-lube during the break in

procedure.

Once

they are removed from the solution, the cams get rinsed off in a fresh

water bath. They are then ready to have the main bearing area

protective material removed. This is also where the camshafts are marked

for warranty protection. All of the cams are marked to identify them as

ours. ( Pictured left is a cam that has been in the Parco tank, lying next

to an untreated cam.) Once

they are removed from the solution, the cams get rinsed off in a fresh

water bath. They are then ready to have the main bearing area

protective material removed. This is also where the camshafts are marked

for warranty protection. All of the cams are marked to identify them as

ours. ( Pictured left is a cam that has been in the Parco tank, lying next

to an untreated cam.)

6. Micro polishing main bearing

areas: This is one of the final steps of processing a camshaft. The camshaft is spun in our polishing machine.

This spins the camshaft at a high rate of speed. A polishing

belt is then used on the bearing areas to remove any discoloration that

may have occurred during manufacturing.

of processing a camshaft. The camshaft is spun in our polishing machine.

This spins the camshaft at a high rate of speed. A polishing

belt is then used on the bearing areas to remove any discoloration that

may have occurred during manufacturing.

7. Protective lubrication and

packaging: Here is the final process  that the camshaft goes through before it is shipped out or placed in the

will-call area for pick up. After the camshaft mains are polished the

camshaft is placed on the rack to be dipped into a rust preventing

lubricant. The camshaft is identified and boxed, and a part # is

stamped on the end of the box. The camshaft is now ready to be shipped or

picked up.

that the camshaft goes through before it is shipped out or placed in the

will-call area for pick up. After the camshaft mains are polished the

camshaft is placed on the rack to be dipped into a rust preventing

lubricant. The camshaft is identified and boxed, and a part # is

stamped on the end of the box. The camshaft is now ready to be shipped or

picked up.

|